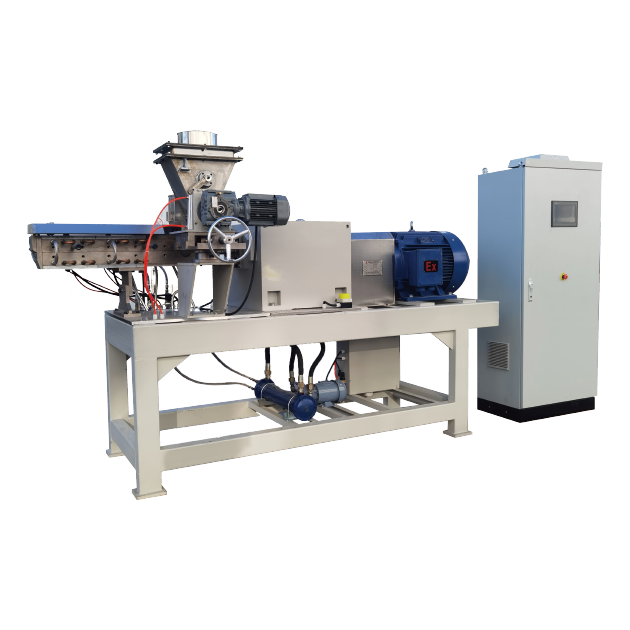

This series of extruder adopts co-rotating twin screw structure. Multi-component raw materials can be fully hot-melted under the precise intermeshing action by the conveying and kneading elements mounted on the screws, to achieve good dispersion and kneading effect.

This series of extruder adopts co-rotating twin screw structure. Multi-component raw materials can be fully hot-melted under the precise intermeshing action by the conveying and kneading elements mounted on the screws, to achieve optimal dispersion and kneading effect.

Integrated with no tailor-welding clamshell barrel design delivering shorter downtime for product change. Homogeneous mixing distribution, high self-cleaning capability.

Hydraulic manual shell opening, ease of cleaning and maintenance.

Time-proven screw configurations providing a broad range of applications.

High quality components, excellent durability and performance for screw elements, liners, barrel and shaft.

Individual lubrication and cooling systems for gearbox, ensuring industry leading performance and lifespan.

Touch screen and PLC long-range Controlled.

Water cooling circulation is regulated by heat exchanger, stainless steel centrifugal pump and tank.

High output, energy efficient.

Low noise, minimal down-time.

Optional: Torque Limiter, Metal Separator

| Model | Output(kg/h) | Screw Speed(rpm) | L/D Ratio | Motor Power(kw) | Heating Power(kw) | Dimension (mm) |

| SLJ-35 | 80-120 | 0-500 | 14-48 | 9.2-11 | 3.2 | 3000*800*1400 |

| SLJ-40A | 120-180 | 0-500 | 14-48 | 15-22 | 10 | 2800*1260*2100 |

| SLJ-50A | 200-300 | 0-600 | 14-48 | 22-37 | 10 | 2700*1400*1800 |

| SLJ-60A | 350-450 | 0-600 | 14-48 | 22-37 | 10 | 2700*1400*1800 |

| SLJ-65A | 500-600 | 0-600 | 14-48 | 37-55 | 12 | 3400*1150*1700 |

| SLJ-75A | 700-800 | 0-600 | 14-48 | 45-90 | 16 | 3400*1150*1800 |