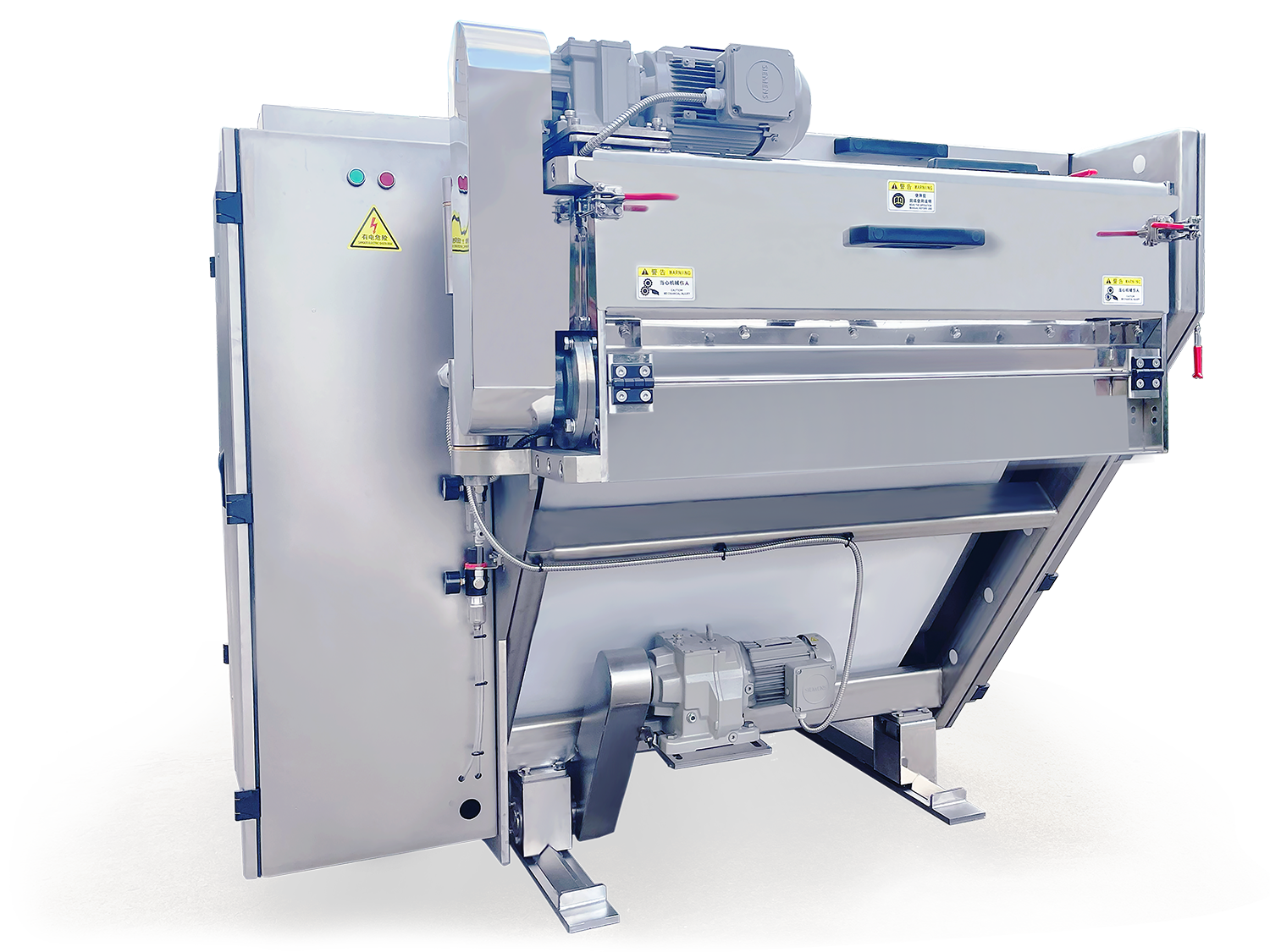

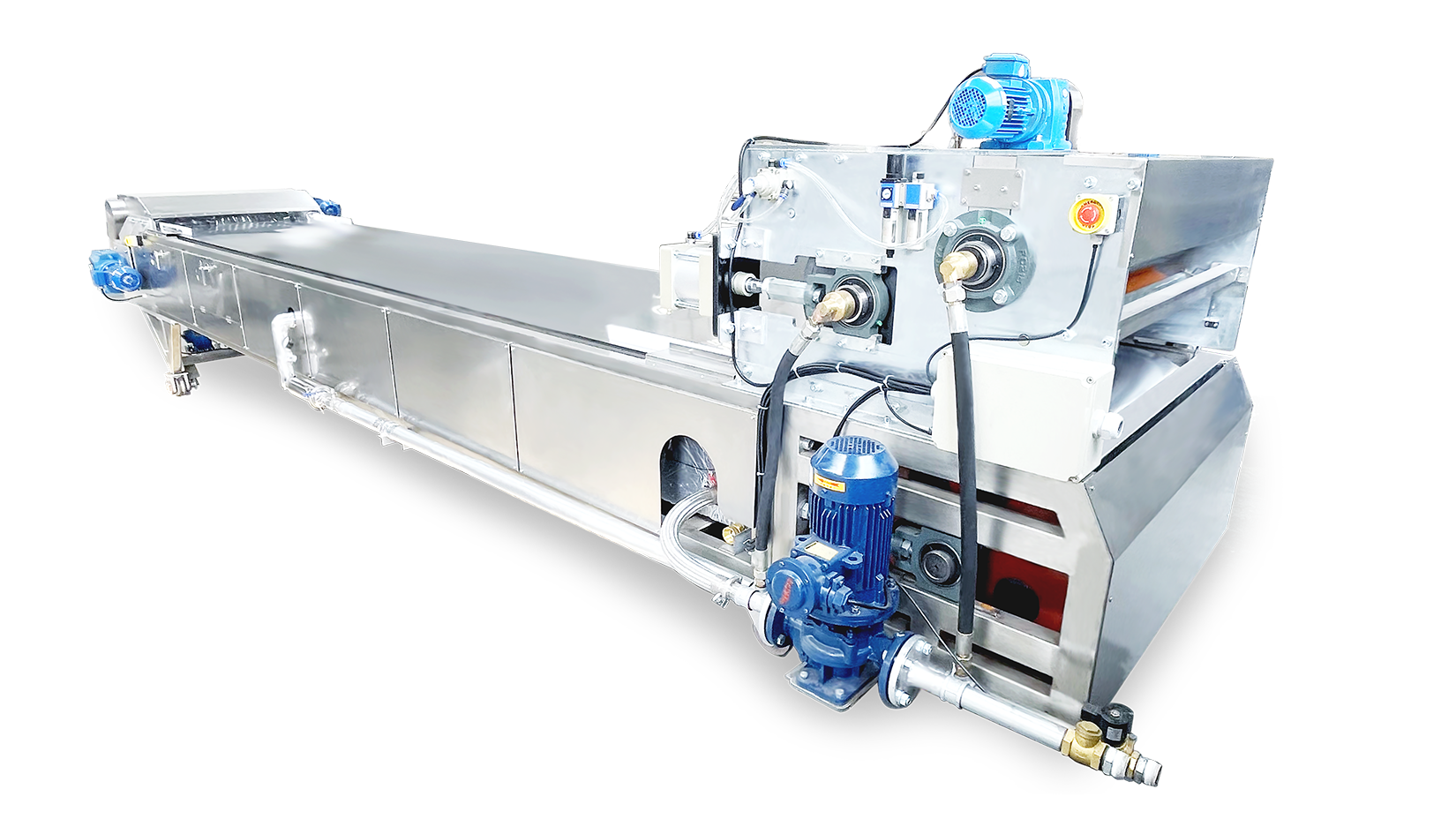

YPR Series Drum Cooler is one of our company's patented products. On the premise of the same output, the long traditional cooling belt is replaced by PU belt. It is composed of cooling roller, cooling drum, PU belt and crusher.The hot-melt materials discharged from extruder are rolled to thin sheet with thickness of 1-2mm by cooling roller and cooling drum, being cooled down by cooling drum to normal temperature during conveying, then being crushed into chips and discharged.

YPR Series Drum Cooler is one of our company's patented products. On the premise of the same output, the long traditional cooling belt is replaced by PU belt. It is composed of cooling roller, cooling drum, PU belt and crusher.The hot-melt materials discharged from extruderare rolled to thin sheet with thickness of 1-2mm by cooling roller and cooling drum, being cooled down by cooling drum to normal temperature during conveying, then being crushed intochips and discharged.

Compact design, short length

Adjustable chip thickness and homogeneous chip size

Optimized crusher design with good sealing, no spatter, no leakage.

Tested good cooling effect

No chip contamination.

Large diameter cooling drum delivering efficient cooling effect, lowering operation costs.

Comprehensive safety system.

Main Technical Parameter

| Model | Output (kg/h) |

Diameter of big roller (mm) |

Small Roller Diameter (mm) |

Belt width (mm) |

Crushing motor (kW) |

Conveying motor (kW) |

Dimension (mm) |

| YPR-50 | 40-60 | 320 | 130 | 400 | 0.12-0.2 | 0.75-1.1 | 855*950*860 |

| YPR-100 | 80-120 | 421 | 155 | 600 | 0.55-0.75 | 1.1-1.5 | 1200*1290*950 |

| YPR-200 | 200-250 | 600 | 215 | 1000 | 0.75-1.1 | 1.5-2.2 | 1600*1720*1420 |

| YPR-300 | 250-300 | 800 | 131 | 1000 | 0.75-1.1 | 1.5-2.2 | 1475*1320*1735 |

| YPR-500 | 400-500 | 880 | 240 | 1000 | 0.75-1.1 | 2.2-3.0 | 1800*1986*1530 |

| YPR-1000 | 600-800 | 1000 | 240 | 1300 | 1.1-1.5 | 2.2-3.0 | 2300*2150*1840 |