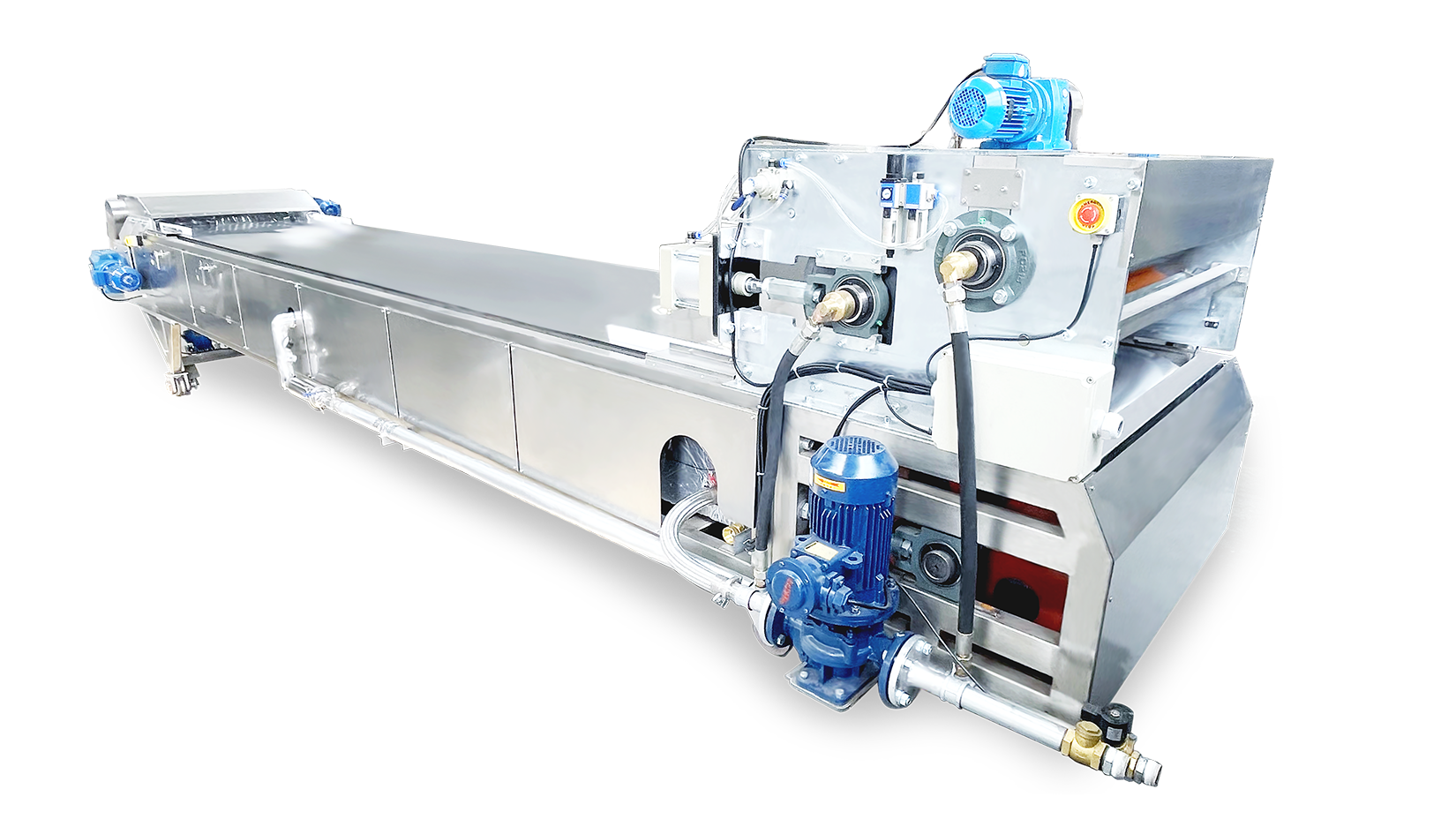

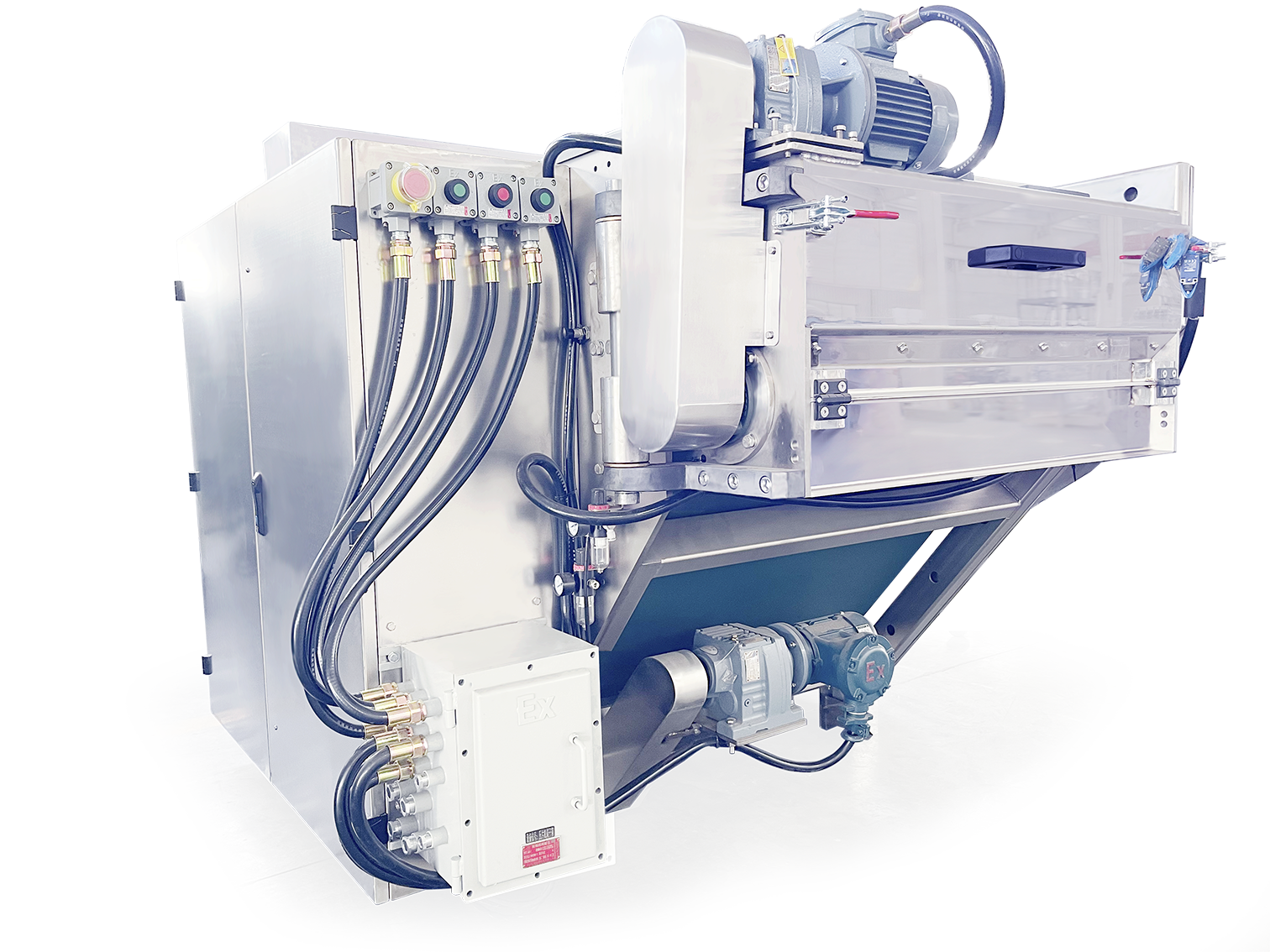

The series of drum coolers features a compact structure, consisting of extrusion rollers, a large-diameter cooling roller, high-strength German conveyor belts, and a crushing unit.

The series of drum coolers features a compact structure, consisting of extrusion rollers, a large-diameter cooling roller, high-strength German conveyor belts, and a crushing unit.

Compact Design- Saves over 65% of workspace compared to traditional cooling belts.

Antistatic & Heat-Resistant Belt- Quick replacement for seamless operation.

Easy Maintenance-Designed for quick cleaning and minimal downtime.

Rotatable Toothed Plate Crusher-Easy to clean and maintain, improving efficiency.

Closed Cooling System-Prevents contamination for a cleaner process.

Large-Diameter Cooling Rollers-Enhances cooling efficiency for faster solidification.

Adjustable Material Thickness-Ensures uniform sheet size and precision.

Reliable Safety Protection-Built-in security features for safe operation.

Main Technical Parameter

| Model | Output (kg/h) |

Cooling Roller Diameter(mm) |

PU Belt Width(mm) |

Crushing Power(kW) |

Conveying Power(kW) |

Dimension (L*W*H-mm) |

| LCD-27/35 | 50 | 270/130 | 350 | 0.37 | 0.55 | 1430*1020*960 |

| LCD-42/65 | 200 | 420/160 | 650 | 0.55 | 0.75 | 1430*1400*1284 |

| LCD-60/90 | 400 | 600/210 | 900 | 0.75 | 1.1 | 1660*1760*1400 |

| LCD-96/100 | 600 | 960/260 | 1000 | 0.75 | 1.5 | 2020*1930*1585 |